There is an increased need for professionals, especially in the automotive industry, to refine their quality skills to meet the needs of the global marketplace. Significant refinements to the ISO/IATF 16944 QMS and the AIAG & VDA FDEA Manual have recently been developed and deployed by Subject Matter Experts within the automotive OEMs, IATF, ISO, AIAG, and VDA. The ISO 9001:2015, IATF 16949, and the AIAG Core Tools, with its updated FMEA, is now better harmonized for integration within your organization’s management systems

QC Training Services has been providing training to professionals that are either unfamiliar with the requirements or need refresher or update training on the new developments. Our training has been providing Professionals with needed insight on how to collaborate effectively and efficiently to integrate these expectations within their companies in order to synergize their operations in satisfying their customers, managing risks, and sustaining continuous improvement efforts.

Examples supporting the need for Core Tools training to achieve this are as follows:

The AIAG & VDA FMEA Handbook was released in June 2019 as the new industry manual for Failure Mode and Effects Analysis.

The AIAG & VDA FMEA Handbook was released in June 2019 as the new industry manual for Failure Mode and Effects Analysis.

- This approach was developed with a global team of OEM and Tier 1 Supplier Matter Experts. The OEMs have developed deployment plans with effectivity dates for their suppliers to comply with.

- It incorporates best practices from both AIAG and VDA methodologies into a harmonized, structured approach and has substantial changes into how suppliers are to develop and optimize Design FMEAs, Process FMEAs, and Supplemental FMEA for Monitoring and System Response (MSR).

- Some of the changes are:

- Use of a Seven Step Approach which includes additional key steps when compared to the prior AIAG manual.

- Use of Action Priorities (AP’s) instead of Risk Priority Number (RPN) thresholds to optimize which was not the approach in the prior AIAG manual.

- More focus on prevention/mistake proofing to mitigate risks and lower the costs of poor quality.

- Use of a FMEA-MSR for safety devices to comply with ISO 26262 “Road Vehicles – Functional Safety”.

- With advanced firmware and computer-based dashboards and driving systems being integrated in vehicles at an accelerated rate, the RISKs that they pose due to failures are even greater. Paradigm shifts in thinking and interlinking are needed to comply with and fully utilize the benefits laid out by AP’s and the MSR approach of this harmonized manual. Obtaining training is highly recommended on how to integrate this with your Optimization/Continuous Improvement efforts.

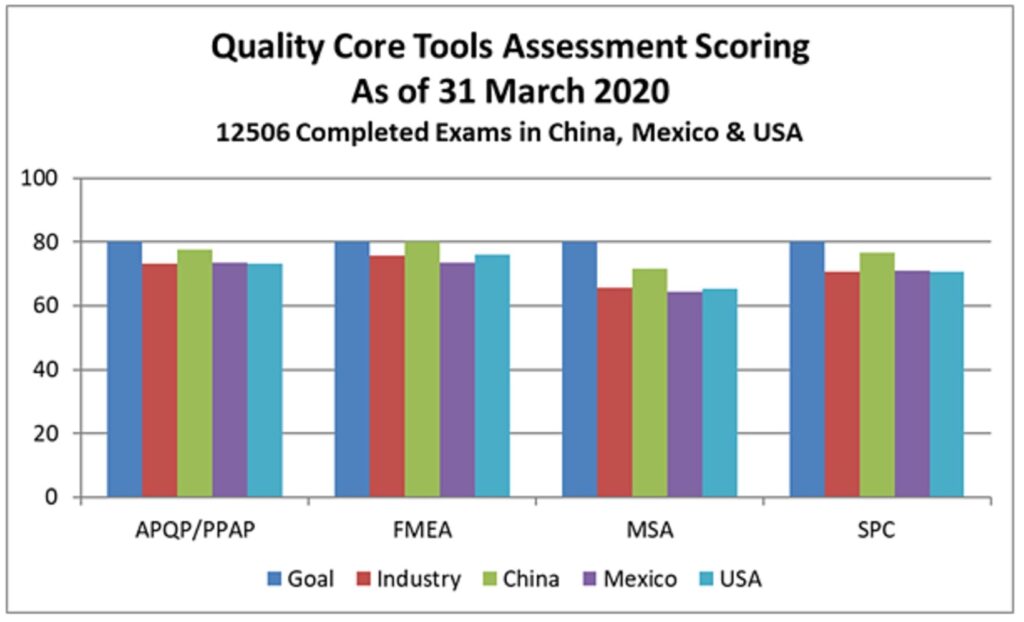

The AIAG recently conducted a Quality Core Tools assessment with over 12,000 professionals in the USA, Mexico, and China.

The AIAG recently conducted a Quality Core Tools assessment with over 12,000 professionals in the USA, Mexico, and China.

-

- As of March 2020, 12,506 participants have completed the open book exams and the average score is less than the 80% goal associated with the APQP/PPAP, FMEA, MSA, and SPC.

- Note: None of the questions were with the new FMEA manual (score would have been significantly lower).

- Training on all the Core Tools is a must and it will ensure proficiency of those individuals. This in turn will help enable Core Tools Professionals to become System and Process Thinkers to provide the greatest Organization benefits on new projects and with sustainment activities (i.e. satisfy customers, reduce the costs of poor quality and reduce other risks/uncertainties). Trained employees have the greatest opportunity to influence their organization towards an effective problem-solving culture. Unarguably, there is an immediate return on investment.

-

- Two (2) years after the release of the IATF 16949:2016, the IATF has reported that organizations are still having difficulties with the transition to meet the requirements and realize the immediate benefits. Part of the challenges is ensuring internal auditors and other professionals understand the requirements with a process mindset and risk-based thinking, which includes ISO 9001:2015, AIAG Core Tools, Total Preventative Maintenance, and associated concepts with Lean, Six Sigma, Continuous Improvement, etc. A proper understanding of the Core Tools is vital to implementation and maintenance.

- Training on this “Umbrella standard” will provide a Quality Management Systems perspective/framework on what is required for an Automotive company to compete in the global marketplace and allow for better teamwork and collaboration. In doing so, the national and international companies will be better prepared to comply with other national and international standards that govern the SAFETY of the end users.

Understanding changes to the new FMEA methodology and improving effective deployment of other supporting Core Tools, will improve product quality and reliability. Training is essential.

We are here to support your organization’s development needs to ensure your workforce is capable of meeting the requirements. Please join in the conversation. What are your biggest challenges with Core Tools in your organization?

Mark Lindsey, QCTS Instructor

CSSBB, CMQ/OE, CQE, & CQA

Anish Shah, QCTS President

MSME, MSMS, MSTM & CQE