Have you or your team embarked on a product or process quality improvement plan only to find a less than desirable solution or no solution at all? As resources are expended, the original problem morphs into a host of other issues that were not anticipated. Undoubtedly, the mistake that was made was to not begin with a Thought Map. This blog touches on the salient points of the process described in the article The Thought Map by Six Sigma Associates – Cheryl Hild, Doug Sanders, and Bill Ross.1 Commonly, the Thought Map is a process that is recommended as a foundational tool in any Six Sigma process improvement project.

The Thought Map is a necessary tool to employ BEFORE any other quality tool is considered. Questions are generated, alternate problem-solving paths are considered, multiple solutions are arrived at, and a ‘where to work first’ and ‘what quality tools are needed’ are understood by deploying this process. The team journey is captured, thereby serving as a historical document wherein work and solutions can be revisited and the process can be communicated to management. In today’s manufacturing world with complex solutions to complex problems, successful projects must begin on a solid foundation. The Thought Map is an invaluable tool for that purpose.

Thought Map

As a skill, the Thought Map is a non-linear thinking method that relies on making connections among unrelated concepts or ideas.  It is a mind map and ongoing document that allows those involved in a project to flesh out ideas, collect existing knowledge, pose questions and create multiple paths towards answering those questions.

It is a mind map and ongoing document that allows those involved in a project to flesh out ideas, collect existing knowledge, pose questions and create multiple paths towards answering those questions.

The Thought Mapping idea in general is outlined in an interesting article referenced below.2 There are many methods to ‘mind map’, however, Six Sigma Associates has adapted this process specifically to the problem-solving environment of today’s manufacturing companies.

Creating an Effective Thought Map

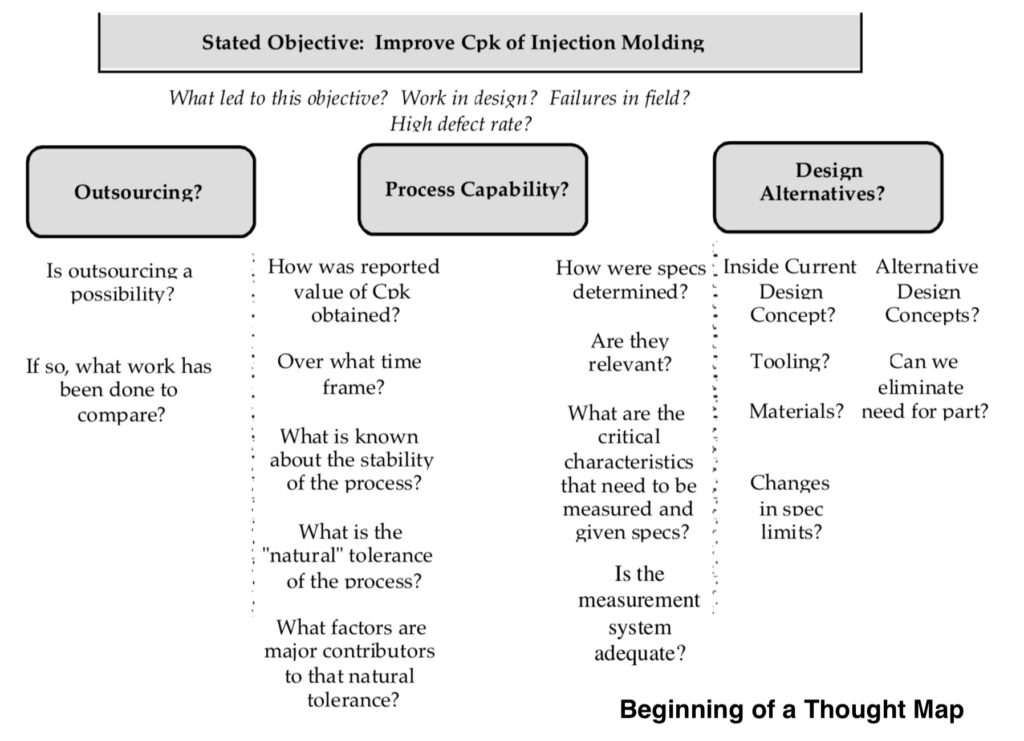

Begin the product/process development project with a stated objective. This is the problem that requires a solution(s). The next steps involve adding the main associations that extend from the stated objective. These top-level associations should constitute the important questions that need to be answered. The thinking must be driven by the questions surrounding the objective. In this stage, all stakeholders across the organization are involved in identifying those questions. Questions drive the solutions, not assumptions or assertions.

In the example above,1 the initial ‘branches’ center on the major alternatives. Note also it questions the relevance of the stated objective. Making these alternatives too specific can limit related associations, thereby restricting questions, ideas, and solutions to the constraints of the one possible path of action. The next level is questions generated from the consideration of each alternative. Consider that without laying down a foundation of these major alternatives, the team is likely to proceed down a single path and neglect to consider the other key pieces to the puzzle.

Branching off from the main questions or ideas may involve adding further questions, suggested tools and methodologies for collecting data, and resource requirements. Invariably, priorities are easily seen as the scope of the problem becomes apparent. The multi-disciplinary team understands what issues should be tackled first and what quality tools will be necessary for the problem-solving process.

Multiple people may take ownership of different branches or sub-branches of a thought map. New branches may be added along with answers to questions. The thought map should continue to grow as each aspect of the project is completed.

When Thought Maps Fail

There is no right way or perfect way to generate a thought map as there are various ways to improve understanding and gain new knowledge. The Thought Map is a powerful communication tool, but there are failure modes that can limit its usefulness. First is by treating it as a static document. Creating a thought map is not a rigid process by its very nature. One of the key elements of a thought map is the ongoing nature of the problem-solving tasks and subsequent documentation. If a thought map is not updated throughout the process, new questions and potential solutions are not captured in order to guide the paths of work. The new knowledge that is gained is lost.

Another failure mode is that questions and theories are not clearly understood, thereby limiting the ensuing logical questions that will define data collection strategies and quality tools that should be used. The thought map provides sequence and connections of thought. It must point to and backup results and conclusions of work done and references to supporting documentation in order to communicate to the team. Documentation of the process shows lessons learned, what data and assumptions that were used, and what are the next questions.

In this post, we have just touched on this vital foundational tool for any project improvement process. For more information, read the full Thought Map paper by Six Sigma Associates.1

If you have questions about using quality tools for improving your business processes or providing training that will educate your teams to effectively tackle your quality improvement projects, QC Training Services can help. Contact our team at 952-746-5725 to discuss your needs.

References:

1 The Thought Map, Six Sigma Associates, Hild, Sanders, and Ross

2 Thought Mapping, University of Leicester, Student Learning Development