Manufacturing is evolving faster than most formal education systems can respond. New materials, tighter tolerances, increased automation, and heightened customer expectations have changed what ‘qualified’ truly means. For adult learners already in the workforce, career resilience now depends on deliberate, practical manufacturing skills training—not waiting for employers or academic institutions to close the gap.

What actions should adult learners take now to sharpen their manufacturing and quality skills—and become more valuable to their employers?

Shift from Credentials to Competence

Degrees and certificates may open doors, but credibility on the shop floor and in engineering roles is earned by solving real problems under real constraints. That means prioritizing learning that improves day-to-day performance: interpreting data correctly, selecting appropriate measurement methods, understanding capability, and navigating audits without disruption.

What QCTS Brings: Instruction grounded in production realities, where learning outcomes are tied directly to applied skills rather than abstract theory—and where examples reflect what actually happens in manufacturing environments.

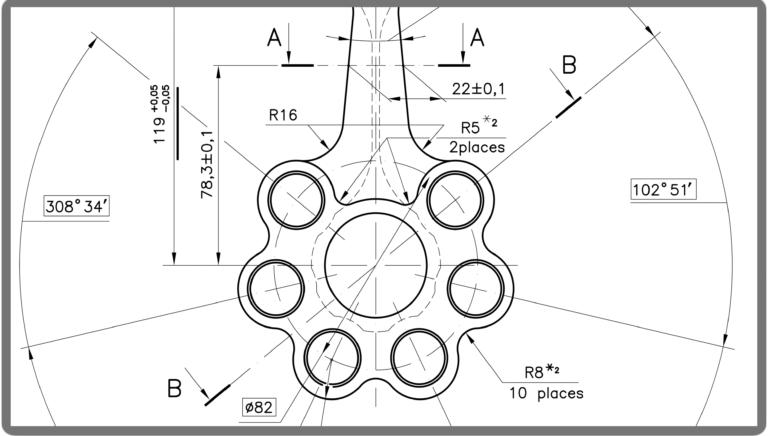

Focus on Depth Over Breadth

Manufacturing rewards individuals who understand why systems fail, not just how procedures are written. Developing depth requires studying variation, measurement systems, root cause analysis, and process behavior—and then stress-testing that knowledge against imperfect data, conflicting specifications, and time pressure.

What QCTS Brings: Practitioner-led manufacturing skills training emphasizing judgment, trade-offs, and failure modes, helping learners move beyond rote compliance toward true technical understanding.

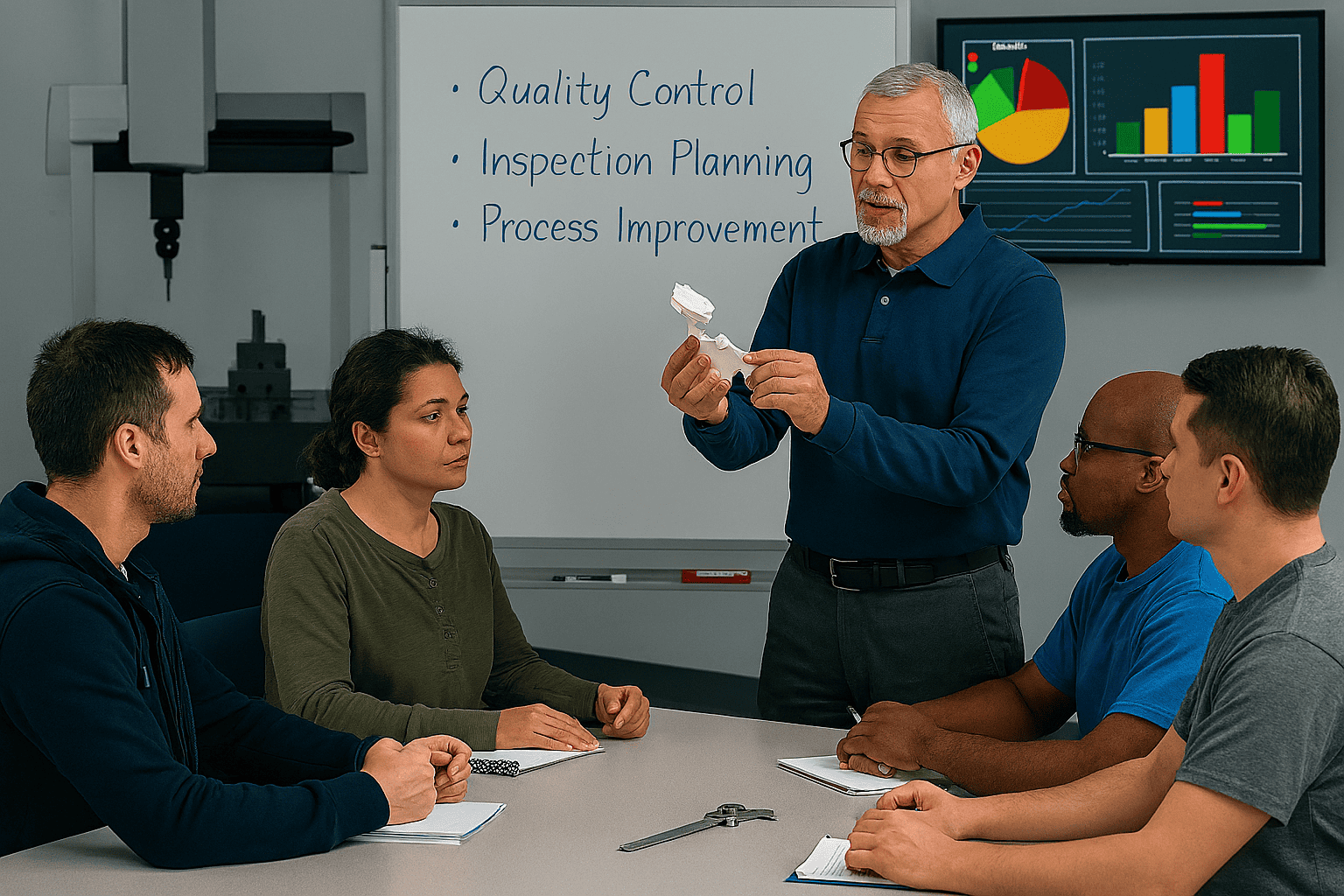

Capture Tacit Knowledge

Much of what keeps production running smoothly is undocumented—passed informally from experienced operators, engineers, and quality professionals. Asking the right questions and recording lessons learned builds intuition that no standard alone can provide.

What QCTS Brings: Access to instructors with deep industry experience who translate hard-won tacit knowledge into structured learning, accelerating what would otherwise take years to acquire organically.

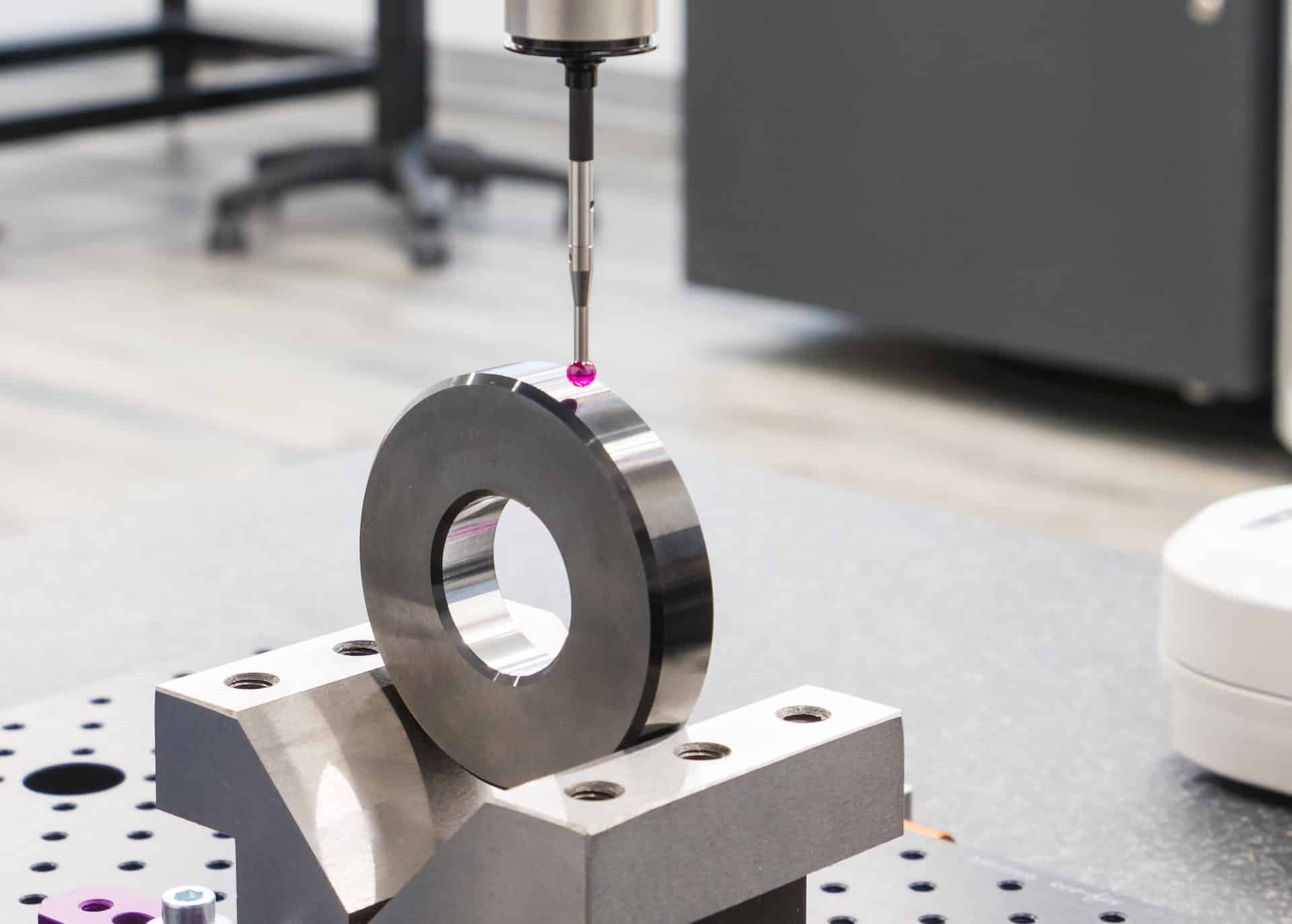

Treat Technology as an Amplifier, Not a Crutch

Software, automation, and AI can speed analysis—but only when users understand the fundamentals. Without strong grounding in statistics, metrology, and process control, technology increases risk rather than reducing it.

What QCTS Brings: Training that reinforces foundational principles first, ensuring participants use tools correctly, defensibly, and with confidence in high-stakes environments.

Align Skill Development with Internal Mobility

Sustainable career growth comes from becoming indispensable—someone who reduces risk, stabilizes processes, and improves outcomes. That requires learning tied to business impact, not résumé padding.

What QCTS Brings: Role-relevant training pathways that help participants translate learning into measurable value for their organization, strengthening both career stability and professional credibility.

In the coming years, manufacturing professionals who succeed will not be those with the most credentials, but those with the strongest applied competence, sound judgment, and production-ready skills. QCTS offers manufacturing skills training that delivers immediate ROI for employers and lasting value for professionals.