Statistical Process Control (SPC) – Basics

Course Delivery: In-Person Training, Virtual Live Training, Training for Teams

This course has multiple delivery options to fit our customers’ individual needs. Click the tabs below for more information on each option.

In-Person Training consists of public classes conducted by one of our subject matter experts at one of our designated locations in one or more consecutive days.

Target Audience

Engineers, production-level workers, technicians, and anyone else who seeks a basic understanding of SPC.

Prerequisites

No prior background knowledge in statistics is required.

Course Objectives

Participants will study effective methods to remove guesswork from quality metrics, eliminate or reduce inspection levels, and increase overall knowledge to improve production processes. Learn the different tools used to analyze data, approaches for variable vs. attribute data, as well as performance vs. capability.

Agenda

- Introduction to SPC

- Data Collection

- Problem Solving Techniques – Critical Thinking, Brainstorming, Flowcharts, Fishbone

- Fundamental Statistical Concepts – Measurements of central tendency and variability

- Descriptive Analysis of Data

- Pareto, Histogram

- Scatter Plot

- Run Chart

- Pseudo Control Chart

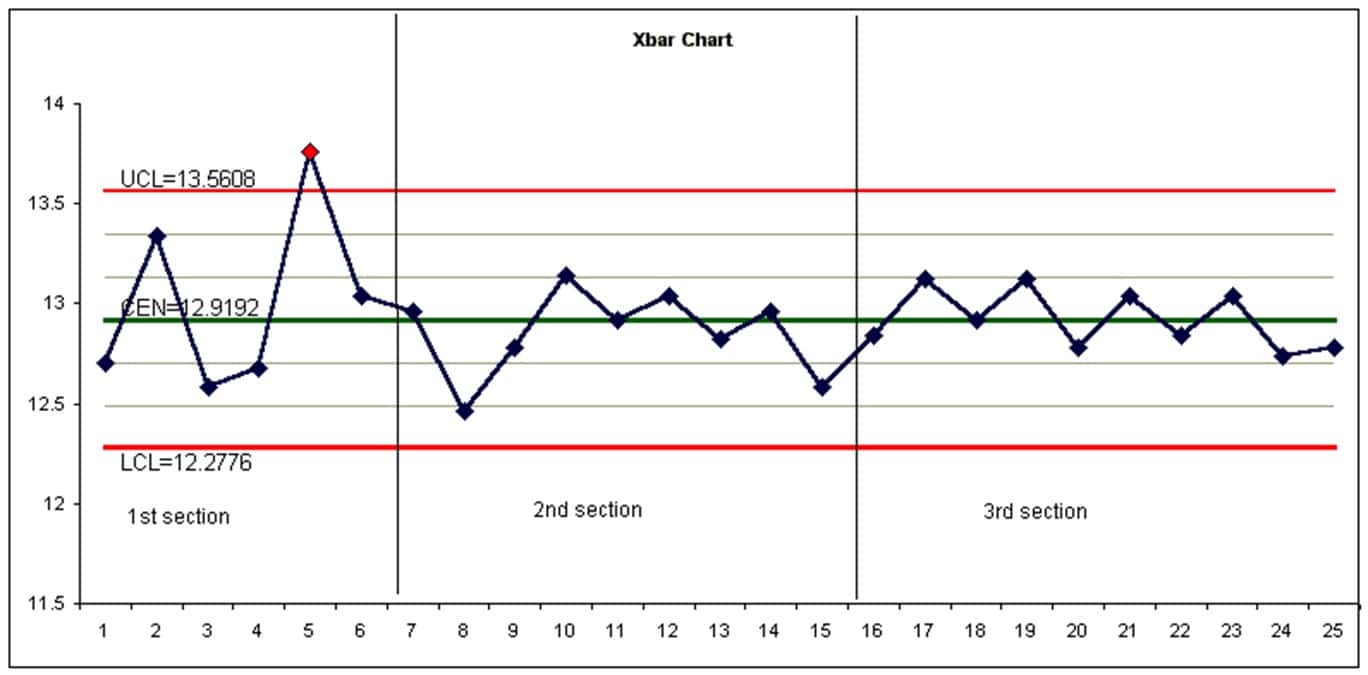

- Control Charts for Variables Data

- Average/Range charts

- Average/Standard Deviation charts

- Average/Moving-Range/Sigma charts

- Run Tests

- Individuals Charts

- Control Charts for Attributes

- p, np, c, and u Charts

- Preparing and Analyzing Charts

- Process Capability

- Capability Ratio – Cr

- Performance Ratio – Pr

- Capability Index – Cp

- Performance Index – Pp

- Process Capability – Cpk

- Process Performance – Ppk

Materials

The Automotive Industry Action Group (AIAG) SPC manual is used as the reference material for this class. Students are asked to bring a scientific calculator, such as the TI30Xa, to this class.

Training Time: 16 hours

Continuing Education Credits (CEUs): 1.6

Our Virtual Live Training classes are conducted through an online platform by one of our subject matter experts in one or more sessions.

Target Audience

Engineers, production-level workers, technicians, and anyone else who seeks a basic understanding of SPC.

Prerequisites

No prior background knowledge in statistics is required.

Course Objectives

Participants will study effective methods to remove guesswork from quality metrics, eliminate or reduce inspection levels, and increase overall knowledge to improve production processes. Learn the different tools used to analyze data, approaches for variable vs. attribute data, as well as performance vs. capability. This virtual course is a condensed version of our in-person 16-hour course.

Materials

The Automotive Industry Action Group (AIAG) SPC manual is used as the reference material for this class. Students are asked to bring a scientific calculator, such as the TI30Xa, to this class.

Training Time: 8 hours

Continuing Education Credits (CEUs): .8

Training for Teams provides training for your group of employees in either a virtual live setting, or in-person at your facility. Connect with us to customize any of our standard courses to fit your specific need.

Currently scheduled classes are shown below. If no classes are displayed, please contact QCTS for other options.