After learning the GD&T concepts, many participants find that they need a methodical way of adding these tolerances into an overall stack-up analysis. The 2-day Tolerance Stacks program is designed for engineers and others who work with stacks.

This course has multiple delivery options to fit our customers’ individual needs. Click the tabs below for more information on each option.

In-Person Training consists of public classes conducted by one of our subject matter experts at one of our designated locations in one or more consecutive days.

After learning the GD&T concepts, many participants find that they need a methodical way of adding these tolerances into an overall stack-up analysis. The 2-day Tolerance Stacks program is designed for engineers and others who work with stacks.

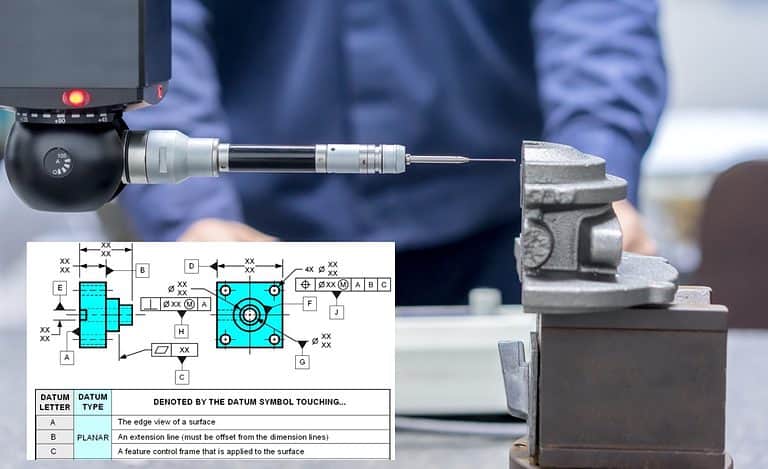

While there is no standard way to do stacks, a spreadsheet method is introduced which allows for both traditional plus/minus tolerances as well as geometric tolerances. We even teach how to handle the MMC “bonus” and “shift” tolerances, which are sometimes ignored, even in “worst-case” stacks.

Training Time: 16 hours

Continuing Education Credits (CEUs): 1.6

Our Virtual Live Training classes are conducted through an online platform by one of our subject matter experts in one or more sessions.

After learning the GD&T concepts, many participants find that they need a methodical way of adding these tolerances into an overall stack-up analysis. The 16-hour Tolerance Stacks program is designed for engineers and others who work with stacks.

While there is no standard way to do stacks, a spreadsheet method is introduced which allows for both traditional plus/minus tolerances as well as geometric tolerances. We even teach how to handle the MMC “bonus” and “shift” tolerances, which are sometimes ignored, even in “worst-case” stacks.

Training Time: 16 hours

Continuing Education Credits (CEUs): 1.6

Training for Teams provides training for your group of employees in either a virtual live setting, or in-person at your facility. Connect with us to customize any of our standard courses to fit your specific need.

Currently scheduled classes are shown below. If no classes are displayed, please contact QCTS for other options.