Coordinate Measuring Machine (CMM) – Advanced

Course Delivery: Training for Teams

This course has multiple delivery options to fit our customers’ individual needs. Click the tabs below for more information on each option.

Training for Teams provides training for your group of employees in-person at your facility. Connect with us to customize this course to fit your specific need.

Target Audience

Inspection, Engineering and Production personnel and those who would like to become more proficient in and diversify their CMM programming skills.

Prerequisites

- Knowledge of Print Reading of drawings with tolerances

- Knowledge of Geometric Dimensioning & Tolerancing

- Knowledge of Basic Dimensional Measurement Tools

- Basic knowledge of PC and Windows

If you lack experience in these areas and you do not pass the pre-skills test, we offer various courses that will give you the knowledge necessary for taking this CMM training. We offer standard public and on-site courses, as well as lower-priced online and self-directed learning courses.

Course Objectives

In this training, participants will expand on their existing knowledge with tips and tricks as well as seldom-used functions to improve performance with respect to productivity (more data in less time) and quality (better data). Special alignments, auto features, constructed features and patterns are all areas of focus. CAD model manipulation and applied GD&T round out the planned topics, always adjusting the training to the skill and experience levels of the participants.

Our instructors are well-versed in PC-DMIS, Calypso, MCOSMOS, CMM Manager, Measure X, and MeasureMind. Whether you’ve got a FARO, Zeiss, Brown & Sharpe, Mitutoyo or OGP application, QC Training Services, Inc. can improve your CMM performance.

Benefits

- CMM instruction by an expert CMM Programmer who is also a Certified Quality Inspector (CQI).

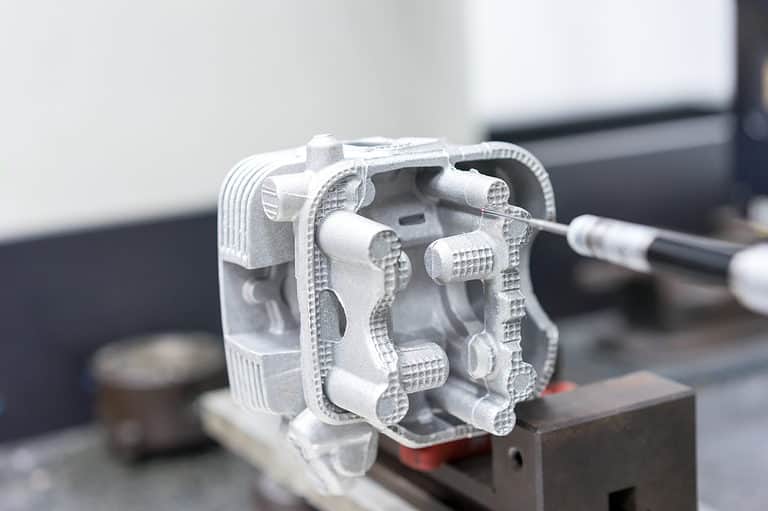

- Hands-on programming using a CMM training block as well as actual manufactured parts.

- Small groups (2-4 students) to allow for maximum learning.

Agenda

- Manual Alignment and 321 alignment review

- Working with CAD files

- Iterative Alignments

- Translation of CAD files (changing origins, changing axes using PC-DMIS)

- Creating a custom toolbar

- Using scans (Linear and UV)

- The use of variables within the program

- Generic features

- Commonly used Auto Features

- Clearplanes

- Accessing the Settings Editor

- Patterns

- Additional goals/topics can be broached depending on customer’s request

Training Time: 24 hours

Continuing Education Credits (CEUs): 2.4

Currently scheduled classes are shown below. If no classes are displayed, please contact QCTS for other options.