Application of Metrology Fundamentals for CMMs

Course Delivery: Training for Teams

This course has multiple delivery options to fit our customers’ individual needs. Click the tabs below for more information on each option.

Training for Teams provides training for your group of employees in either a virtual live setting, or in-person at your facility. Connect with us to customize any of our standard courses to fit your specific need.

Target Audience

This course is designed for inspection personnel, engineering personnel, production personnel, entry level inspectors, and those who would like to enter into the field of dimensional measurement and CMM programming.

Course Objectives

- What is a VALID result?

- How does one maintain traceability?

- International vocabulary of metrology – Basic and general concepts and associated terms (VIM)

- Precision

- Gage R&R

- Bias

- How to avoid failing BIAS test

- When we fail BIAS, how do you move forward?

- Accuracy

- What is a Calibration?

- Understanding errors inherent to CMMs

- Calibration intervals and interim artifact testing

- ISO 1 – it was the start to this successful application

- How are these standards tied to each other and within the industrial segments?

- Almost all the new technologies are software driven

- Manual, semi-automatic, automatic – Stationary as well as portable solutions

- International vocabulary of metrology – Basic and general concepts and associated terms (VIM)

- How to interpret a system specification?

- Is measurement uncertainty listed and if so, why is it important?

- TAR and TUR

- Hole fitting algorithm – know that they exist, what they mean, and how to choose which to use in each situation

- Least squares

- Maximum inscribed circle

- Minimum circumscribed circle

- Lighting considerations and how they affect the results

- Top vs. bottom lighting

- Fiber/fluorescent/coaxial (through the lens) lighting

- Light intensity (washing out edges)

- Color

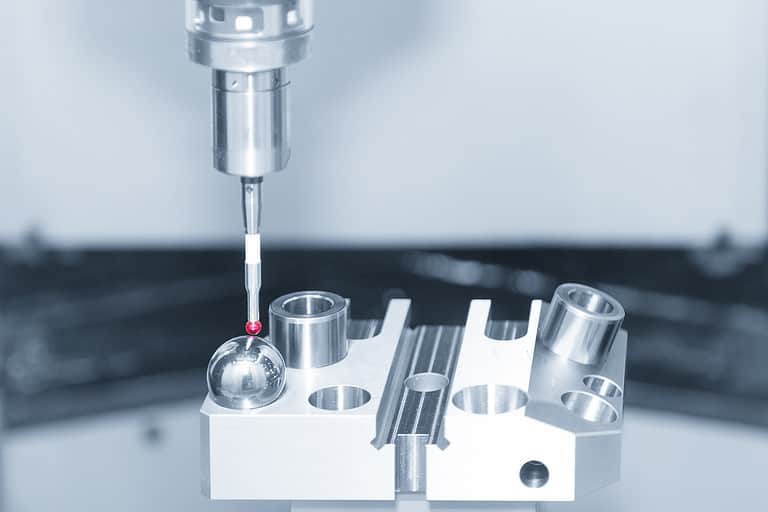

- Contact CMM probing factors

- Probe type

- Probe size

- Probing contact/approach angle and Cosine error

- Probing speed

- Effect of scanning vs probing technique on measurements.

- Interaction with part being measured

- Rounded edges (top vs bottom lighting)

- Reflectivity

- Hardness (for contact gaging)

- Fixturing

- Measurement Uncertainty

- Basic concepts

- Estimation process

- Hole fitting algorithm – know that they exist, what they mean, and how to choose which to use in each situation

Training Time: 16 hours

Continuing Education Credits (CEUs): 1.6

Here’s what students have had to say about this training:

“Liked the small class size. Lots of time on CMM.” – Dan, Minnesota

“This 3 day course was very beneficial and I would recommend this to other co-workers.” – Bridget, Wisconsin

Currently scheduled classes are shown below. If no classes are displayed, please contact QCTS for other options.